From Digital Design to Physical Object

Every product at Volmer Manufaktur begins as a digital idea, a 3D model on a computer. The path from idea to reality leads through additive manufacturing - a process in which an object is built up precisely, layer by layer.

We specialize in the FDM process (Fused Deposition Modeling). In this method, a precise print head melts the material and deposits it in exact, fine paths until the finished component is created.

Quality Through a Controlled Process

For us, 3D printing is a precise manufacturing method. The difference between a good result and an outstanding one lies in the control over the process. We rely on professional manufacturing systems to ensure this control with every single print.

1. A Stable Process Environment

The key to a perfect print is a stable environment. Our manufacturing systems feature a fully enclosed build chamber.

This enclosed chamber is a decisive quality feature: it prevents drafts and stabilizes the ambient temperature. This is beneficial for many materials, as it minimizes "warping" (the distortion of the component) in large objects and ensures a consistent, strong layer bond throughout the entire print.

Project-based, this build chamber can additionally be actively heated for technical plastics. This high process temperature is mandatory for such materials to reduce component stress and enable stable manufacturing.

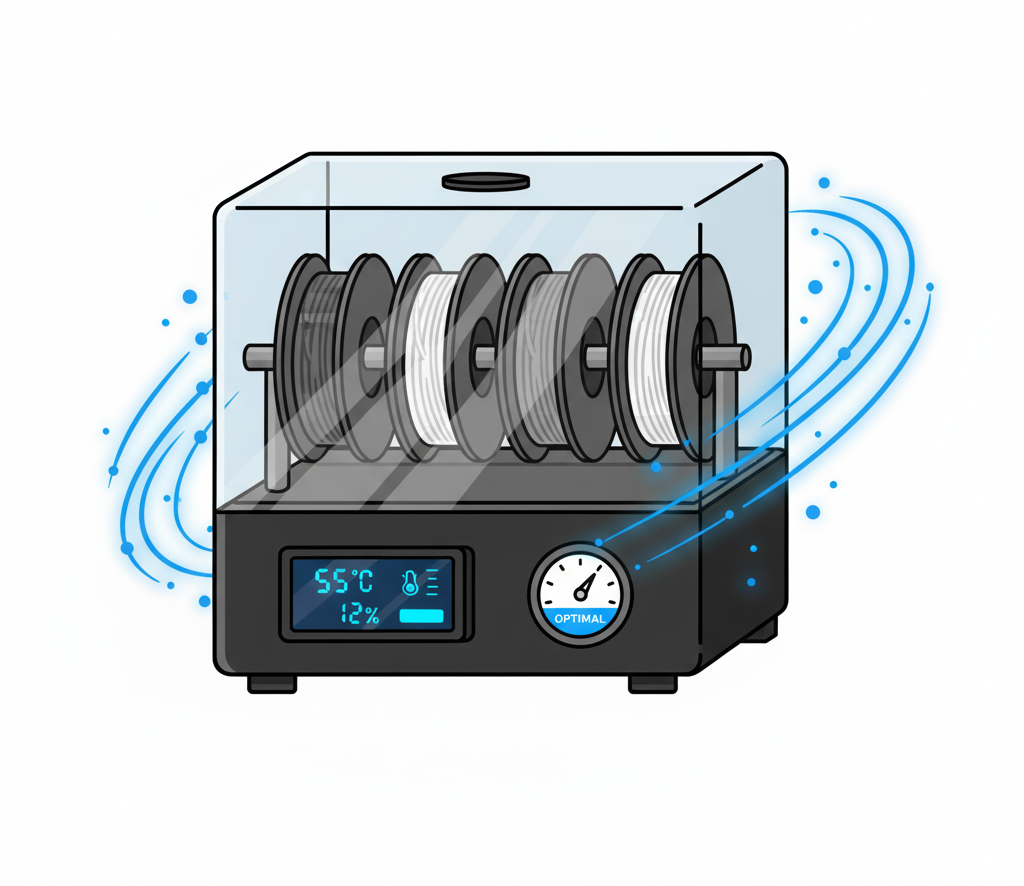

2. Active Material Management

Many plastics (especially technical ones) absorb moisture from the air - they are hygroscopic. If moist filament is printed, the quality suffers visibly.

That is why, depending on the requirement and type, our material is conditioned before and during processing. This is an often overlooked but crucial step for clean extrusion and a flawless surface.

Our Material Philosophy

Primary Material: Sustainable PLA

For our puzzle boxes and design objects - products intended for daily use in living or working areas - high-quality PLA (Polylactide) is our first choice.

This plant-based material is non-toxic, odorless, and sustainable. It offers excellent surface quality and detail fidelity, which is ideal for the complex mechanics and fine aesthetics of our products.

Furthermore, the material impresses with a pleasant, robust feel that underscores the high-quality character of every single object.

Technical Plastics: For Special Requirements

Project-based, when a prototype or functional part requires extreme durability, abrasion resistance, or heat resistance, technical plastics are used.

In these cases, the actively heated build chamber allows us to reliably process demanding materials such as ASA, ABS, or fiber-reinforced composites (e.g., PETG-CF or PA-GF) to manufacture components with specific mechanical properties.

This ensures that our technical prints are not merely visual prototypes but resilient functional parts ready for real-world application and rigorous testing.